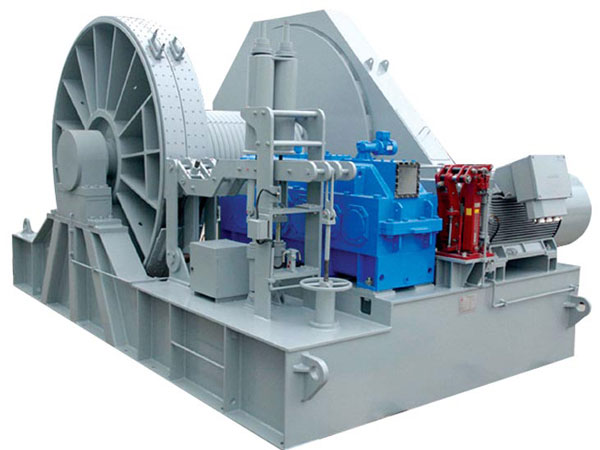

Electric tugger winch is a great choice for dragging material with long distance.

- It can save mush energy, labor resource, increase efficiency and improve working condition.

- It has complete safety protection devices, such as overload protection, overs-speed protection, emergency brake etc.

- Security devices can avoid accidents, protect tugger winch from damage and prolong winch service life.

Aimix, a professional and famous marine winch manufacturer in China, provides a number of top winches, such as marine electric winch, marine hydraulic winch, offshore winches, electric cable winch, gypsy winch, constant tension winch, electric trailer winch, cable pulling winch, cheap boat winch, horizontal anchor windlass, drum anchor winch for sale, good windlass for sale, constant tension mooring winches, hydraulic towing winch and electric towing winch.

Buy Aicrane boat winches for durable material, great performance, ideal price, reliable quality and reasonable design!

Get great deal for suitable winch from us!

Load capacity: 10 ton – 100 ton

Drum capacity: 500m- 1500m

Speed: 5m/min – 20 m/min

No. of drum: single or double

Certificate: BV, ABS, DNV, RMRS, etc

Get a Free Quote

Usual obstacles of electric tugger winch

First, the winch has loud noise. The frame is not smooth, and open gear has bad contact. Concentricity of coupling doesn’t meet requirement. The tugger winch is overload, over-speed. The lubrication is not good. Check and adjust, reduce load, operate according to standards, strengthen lubrication.

Second, winch is weak, electric motor produces heat, electric current exceeds rated current. Operating voltage is too low, the winch is overload, heat dissipation of electric motor is not effective, and three phase current is not balance. Increase cable diameter, cut distance between winch and transformer. Reduce load or slow down the speed, strengthen heat dissipation, check and take measures to solve problems.

The arrangement of wire rope on the drum is disorder. The winch is installed partially, pulley and drum center line are deflected. Principle axis is not horizontal, wire rope rotates on the drum too much, adjust the level of principle axis, rotate wire rope according to standards and reduce rotating width.

Fourth, the winch vibrates seriously. Shaft axis of coupling are not properly aligned. Anchor bolts are not fastened firmly. Check, adjust and tighten.